Electrostatic discharge sensitive components (ESDS) are electronic devices that can be damaged by electrostatic discharge (ESD). ESD occurs when two objects with different electrical potentials, such as a charged human body and an electronic component, come into contact. The resulting sudden flow of electricity can cause irreversible damage to sensitive components, leading to device failure or reduced performance. In this article, we will discuss the grading system for ESDS components, various damage cases in the electronics industry, and the statistics related to device losses.

SSD Grading

To help manufacturers and users understand the ESD susceptibility of different components, the industry has established a grading system. The grading system classifies components based on their ability to withstand ESD events without damage. The primary grading standards include the Human Body Model (HBM), the Machine Model (MM), and the Charged Device Model (CDM).

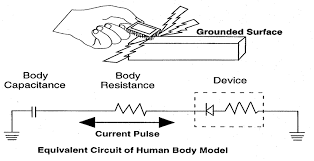

Human Body Model (HBM)

HBM simulates ESD events that occur when a charged human body touches an electronic component. It is the most common ESD event and can cause significant damage. HBM grading is based on the voltage level the component can withstand without damage, and it is divided into several classes:

- Class 0: < 250 volts

- Class 1A: 250 – 499 volts

- Class 1B: 500 – 999 volts

- Class 1C: 1000 – 1999 volts

- Class 2: 2000 – 3999 volts

- Class 3A: 4000 – 7999 volts

- Class 3B: ≥ 8000 volts

Machine Model (MM)

The MM simulates ESD events that occur when a charged machine, such as a soldering iron or test equipment, comes into contact with an electronic component. It is less common than HBM but can cause more severe damage. MM grading is also based on voltage levels, with classifications as follows:

- Class M0: < 100 volts

- Class M1: 100 – 199 volts

- Class M2: 200 – 399 volts

- Class M3: 400 – 799 volts

- Class M4: ≥ 800 volts

Charged Device Model (CDM)

CDM simulates ESD events that occur when a charged component is suddenly discharged through a conductor, such as a grounded surface or another component. CDM events can be particularly damaging as they often involve high peak currents. CDM grading is based on the peak current the component can withstand without damage, with classifications as follows:

- Class C0: < 125 mA

- Class C1: 125 – 249 mA

- Class C2: 250 – 499 mA

- Class C3: 500 – 999 mA

- Class C4: ≥ 1000 mA

Electronic Industry Electrostatic Damage Cases and Statistics

Statistics of Electronic Device Losses

ESD is a significant concern in the electronics industry, as it can lead to costly device failures and reduced performance. The Electrostatic Discharge Association (ESDA) estimates that ESD-related losses cost the global electronics industry around $5 billion annually. This includes direct costs, such as component replacement and repair, as well as indirect costs like lost productivity, customer dissatisfaction, and brand damage.

Approximately 60-70% of all electronic device failures can be attributed to ESD, with a significant portion occurring during manufacturing and assembly processes. The implementation of proper ESD control measures can reduce these losses by up to 95%.

Typical Cases

Here are some typical cases of ESD damage in the electronics industry:

Semiconductor Manufacturing

In a semiconductor manufacturing facility, an electrostatic discharge event caused damage to a batch of microprocessors, resulting in a 70% yield loss. The incident was traced back to an improperly grounded conveyor belt, which caused a buildup of static charge on the devices. The total cost of the incident was estimated at $1.5 million.

Aerospace Industry

An aerospace company experienced a series of unexplained failures in a satellite’s solar panel system during ground testing. Upon investigation, it was discovered that ESD events during assembly had damaged the sensitive solar cells. The damage was not immediately apparent, but the cells degraded rapidly under operational conditions. The cost of the investigation, rework, and delayed launch was estimated at $10 million.

Consumer Electronics

A popular smartphone manufacturer faced a recall due to a significant number of devices experiencing touchscreen failures. ESD events during assembly were identified as the cause, as the devices were not properly protected from static discharge. The cost of the recall, customer dissatisfaction, and brand damage was estimated at $50 million.

Automotive Industry

An automotive manufacturer experienced intermittent failures in a vehicle’s electronic control unit (ECU), leading to performance and safety concerns. Investigation revealed that ESD events during assembly had damaged some of the ESDS components in the ECU. The cost of replacing the affected units and implementing new ESD control measures was estimated at $2 million.

Summary

Electrostatic discharge sensitive components (ESDS) are critical elements in modern electronics, making the understanding and management of ESD events essential for the industry. The grading system for ESDS components, including the Human Body Model (HBM), Machine Model (MM), and Charged Device Model (CDM), helps manufacturers and users assess the ESD susceptibility of different devices.

The electronics industry faces significant losses due to ESD-related damage, with an estimated $5 billion in annual costs. Understanding the various ESD damage cases, such as those in the semiconductor manufacturing, aerospace, consumer electronics, and automotive industries, highlights the importance of proper ESD control measures. By implementing effective ESD protection strategies, the industry can significantly reduce these losses and ensure the reliability and performance of electronic devices.

In conclusion, electrostatic discharge sensitive components are a vital aspect of the electronics industry. Awareness of their grading system, damage cases, and industry statistics is crucial for manufacturers, users, and professionals in the field to maintain the highest levels of product quality, safety, and reliability.

Leave a Reply

Want to join the discussion?Feel free to contribute!