Electrostatic discharge (ESD) is a common phenomenon that occurs when two surfaces come into contact and then separate, leading to the transfer of charge between them. In production and usage environments, ESD can cause significant damage to sensitive electronic components, resulting in product failures and costly repairs. This article will discuss the primary sources of electrostatic charge, particularly focusing on the human body and its products, as well as the strategies to protect against ESD in production and usage environments.

Human Body Static Electricity and Human Body Products

The human body is a major source of electrostatic charge due to its ability to accumulate and store charge on its surface. This charge accumulation can occur through various means, such as through the friction generated by walking or the contact and separation of clothing materials. As people interact with electronic devices and equipment, there is a potential for ESD events that can damage sensitive components.

Charging Methods for Human Body Static Electricity

There are several ways in which the human body can accumulate electrostatic charge. Some of the most common charging methods are:

- Triboelectric charging: This occurs when two materials with different electron affinities come into contact and separate, causing the transfer of electrons from one material to the other. The human body can become charged through friction, such as walking across a carpeted floor, or through contact with clothing materials.

- Capacitive coupling: This charging method occurs when a charged object (such as a metal tool) comes into close proximity with another object (such as a human body). The presence of the charged object causes the redistribution of charges within the nearby object, leading to the accumulation of charge on its surface.

- Electrostatic induction: This charging method involves the redistribution of charges within an object in response to an external electric field. When a charged object is brought close to the human body, the charges within the body redistribute themselves to minimize the total energy of the system.

Human Body Products

Several products are derived from the human body that can contribute to electrostatic charge accumulation. Some examples of these products are:

- Clothing: As previously mentioned, clothing materials can generate charge through triboelectric charging when they come into contact and separate from the human body. Synthetic materials, such as polyester and nylon, are particularly prone to generating electrostatic charge due to their high electron affinity.

- Shoes: Footwear can also contribute to the accumulation of electrostatic charge on the human body. Shoes with insulating soles can prevent the dissipation of charge from the body to the ground, leading to the buildup of charge on the person’s body.

- Personal items: Objects that people carry with them, such as cell phones, keys, and wallets, can also accumulate charge through contact and separation with other materials. These charged objects can potentially cause ESD events when they come into contact with sensitive electronic devices.

Electrostatic Protection in Production and Usage Environments

To minimize the risk of ESD-related damage in production and usage environments, it is crucial to implement appropriate electrostatic protection measures. Some of the most effective strategies include:

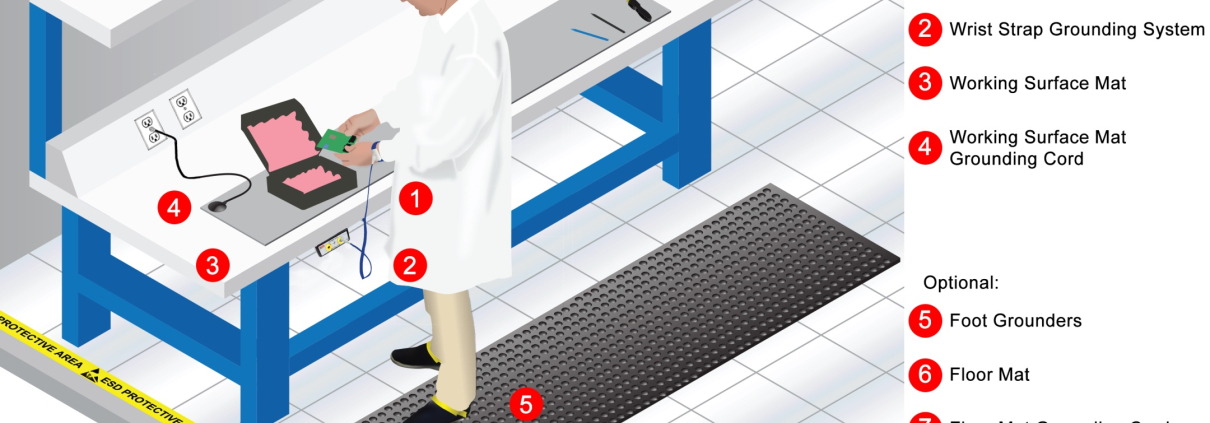

- Electrostatic Discharge Protected Area (EPA): Establishing an EPA involves creating a controlled environment where all conductive materials are grounded, and all insulating materials are either removed or neutralized. This can include using grounded work surfaces, anti-static flooring, and grounded wrist straps for personnel.

- Proper grounding: Ensuring that all personnel, equipment, and work surfaces are adequately grounded is one of the most critical aspects of ESD protection. This can be achieved through the use of grounding cables, wrist straps, and conductive footwear.

- Humidity control: Maintaining an environment with a relative humidity level of around 40% to 60% can help reduce the risk of ESD events, as moisture in the air can help dissipate electrostatic charges.

- ESD-protective packaging: When transporting and storing sensitive electronic components, it is essential to use packaging materials that provide protection against ESD. This can include using conductive bags, anti-static foam, and other ESD-safe packaging materials.

- ESD training: Providing proper training to personnel on the risks associated with ESD events and the proper handling of sensitive electronic components is essential for minimizing the likelihood of ESD-related damage.

- Regular audits and assessments: Regularly assessing the effectiveness of the implemented ESD protection measures and making necessary adjustments is crucial for maintaining a safe working environment.

Summary

Consequently, understanding the sources of electrostatic charge, particularly those related to the human body and its products, is essential for effectively managing electrostatic risks in production and usage environments. By implementing appropriate protection measures, such as establishing an EPA, ensuring proper grounding, and providing employee training, businesses can reduce the likelihood of ESD-related damage and maintain the integrity of their electronic components. Regularly assessing these protection measures and making necessary adjustments will ensure a continuously safe working environment, ultimately saving time and resources in the long run. By being proactive in addressing electrostatic threats, businesses can safeguard their investments and maintain the highest standards of quality and reliability in their products.

Leave a Reply

Want to join the discussion?Feel free to contribute!