The ESDP work surface (Reference ESD TR20.20-2008, section 5.3.1 – Work surfaces) will provide a safe path to ground for static charges within the operator’s general working area. Either the ESDP work surface may be fabricated as a part of the workbench or it may be a separate addon item. In either case, the ESDP work surface shall be grounded and static dissipative with a resistance to ground measurement between 1×106 to 1×109 ohms. Applications where hard grounding of the LRU is required are excluded. ESD S4.1 “ESD Association Standard Method for the Protection of ESDS Items – Workstation – Resistive Characterization” describes the test methods for work surfaces. Grounding of the work surface may be accomplished with the use of a current limiting resistor that is generally a ¼ watt, 250V part. The maximum voltage rating of the resistor defines the maximum working voltage of the surface. The use of a series resistor is recommended for personnel safety if the currents from accessible voltages at the workstation could exceed 5mA through the static-dissipative protective work surface. For personnel safety, the use of a ground fault circuit interrupter (GFCI) is recommended in situations where personnel may come in contact with hazardous current levels.

The ET&V Officer shall check the work surface ground continuity during initial certification. Thereafter this check can be done by lab personnel on a weekly basis. It is strongly recommended that electronic monitors be used to monitor continuously the integrity of the work surface ground.

The manufacturer’s recommended chemicals and methods that will not damage the work surface shall be used to clean the work surface as required.

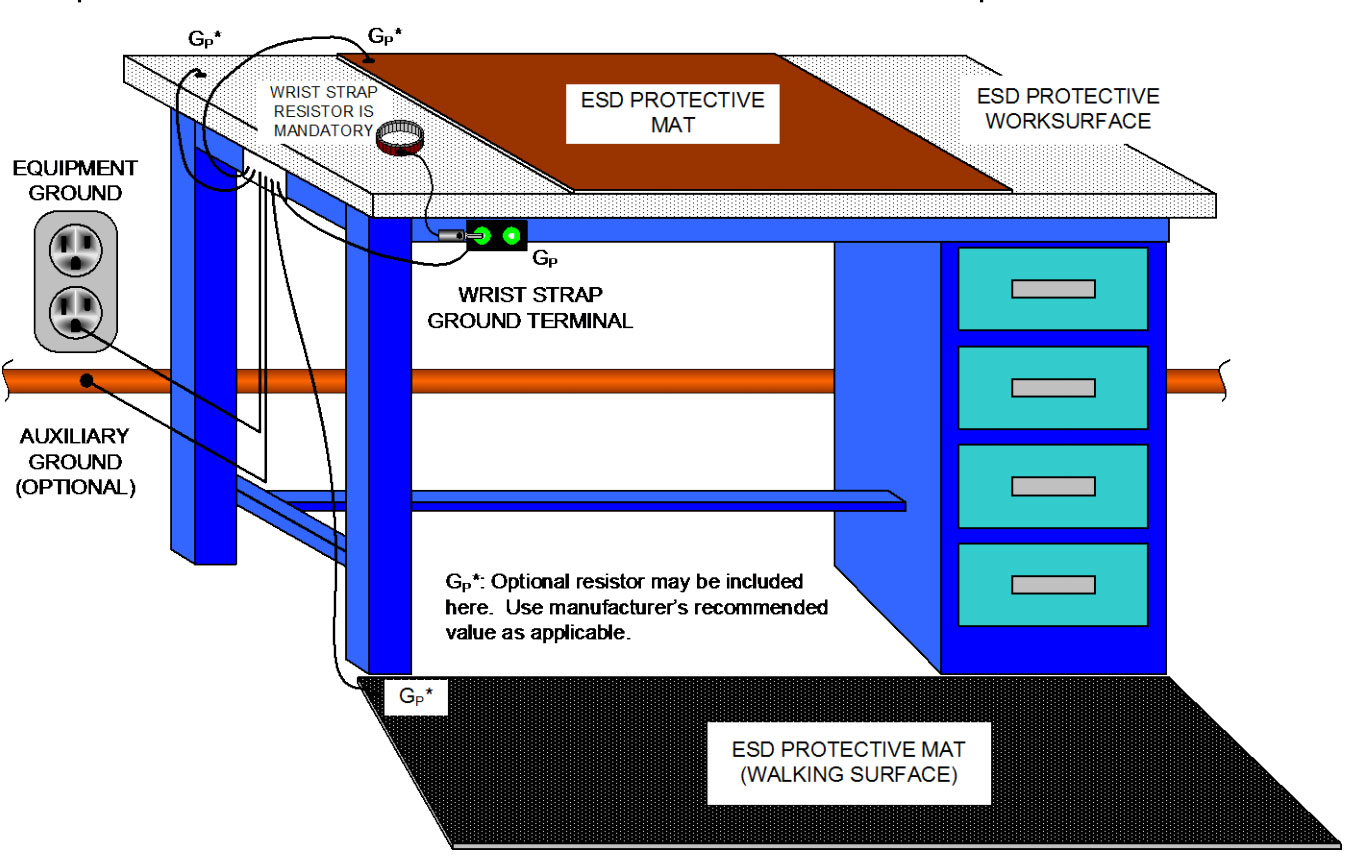

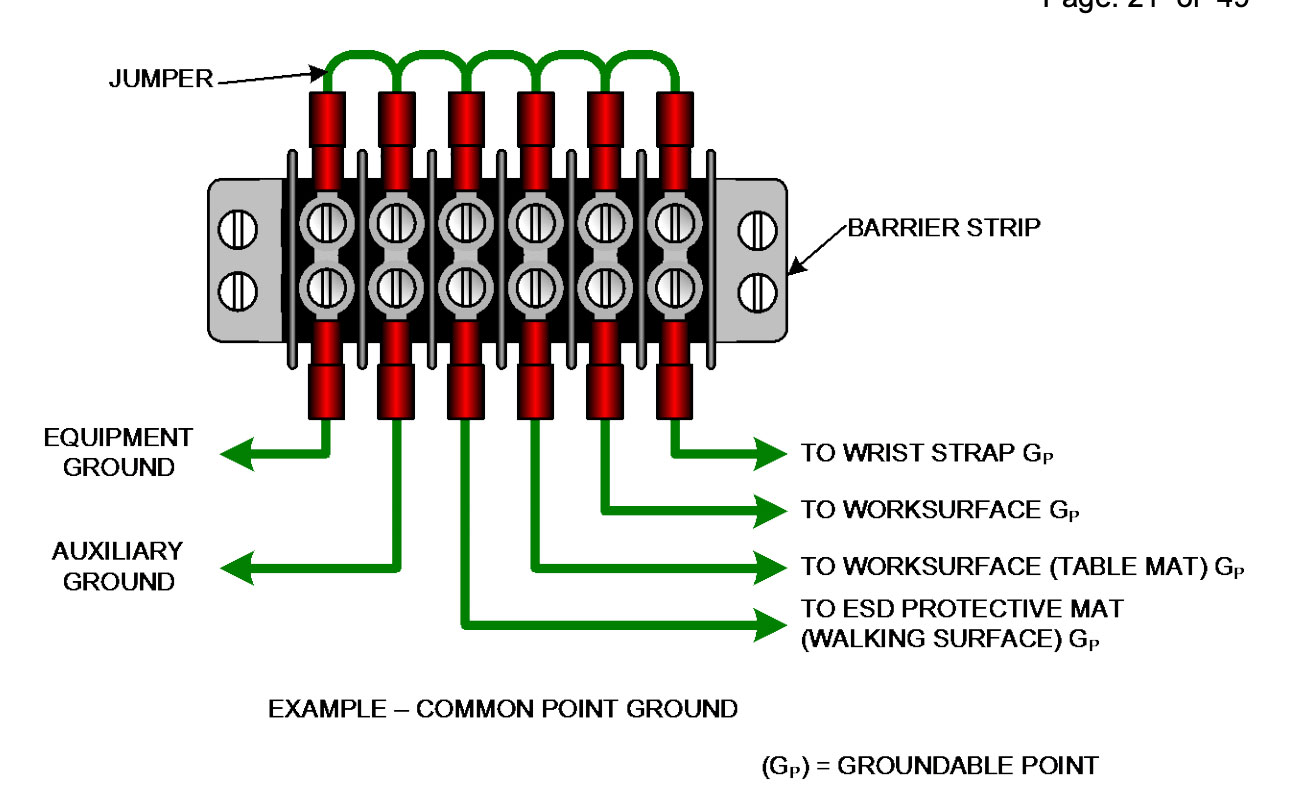

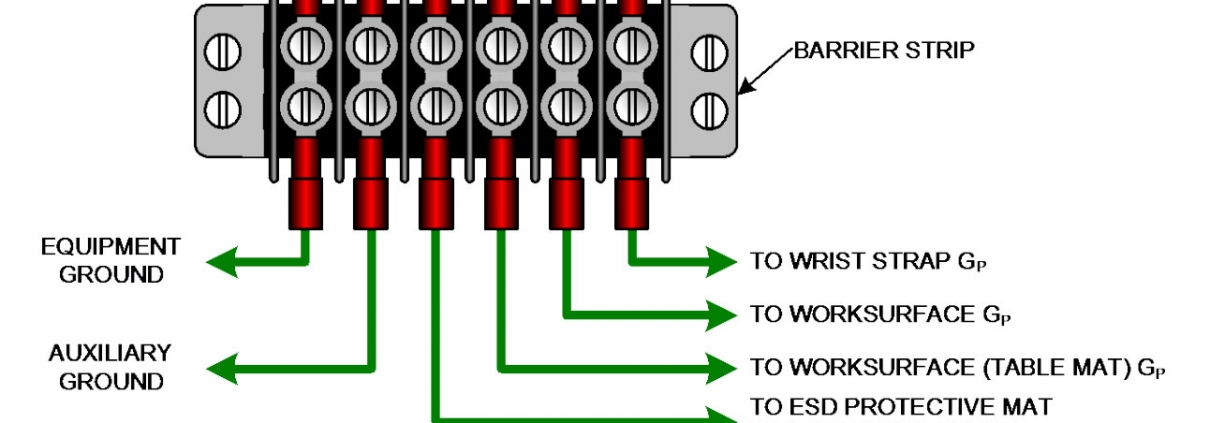

Exposed metalwork surfaces are not acceptable for ESD workstations. If a special situation requires a conductive work surfaces, it must be hard grounded. If a painted metal bench is used, the metal must be covered with a static dissipative material. See Figure 6.5.1 and Figure 6.5.2 for examples of how a workstation should be connected to meet ESD requirements.

Figure 6.5.1 Typical ESD Protective Station Grounding Systems

Figure 6.5.2 Typical Barrier Strip Common Ground Point

Leave a Reply

Want to join the discussion?Feel free to contribute!