China has become the processing base of electronic products, in the Pearl River Delta and Yangtze River Delta Regions, a large number of electronic enterprises have been established. At present, the vast majority of ESD control job in these enterprises doesn’t follow ESD 20.20 in accordance with American standards. The ESD control work in factories is nothing more than to purchase simple ESD supplies such as anti-static work clothes and wristbands, which is far from ESD 20.20 standard.

Name

ESD Testing/Electrostatic Discharge Testing

Reference Standard

EN61000-4-2

Corresponding National Standard

GB/T 17626.2

Catalog

- 20.20 Certification

- 20.20 Standard

- Related Certification

- Applicable Industries

- Key Benefits

- Relevant Criteria

- Background

- Circumstances

- Types

- Models

20.20 Certification

Many enterprises are often rejected because of ESD problems after thorough preparations, when they encounter on-site audits of foreign customers. The improvement of ESD technology level is the top priority of the whole electronic industry, and the promotion and popularization of ESD system standards is an arduous task.

20.20 Standard

NSI/ESD S20.20:2007 is an accreditation project officially launched by ESD Association of United States in 2000. The association is composed of manufacturers and users of electronic components. Its main members include IBM, MOTOROLA and other companies. OEM factories or suppliers of these companies must pass ESD S20.20 accreditation in order to obtain and maintain credentials as OEM and products suppliers. Therefore, it can be considered that ESD20.20 is a buyer’s certification standard. For manufacturers of chips, electronic components, power supplies and plug converters, and displays, ESD20.20 is considered a compulsory certification in order to become a well-known brand supplier.

Related Certification

ESD certification is based on ANSI/ESD S20.20, which is to certify the ESD system of enterprises (including documents, personnel and protective facilities, etc.). ESD standard is a specific requirement for ESD protection and control system based on ISO 9001. The standards clearly stipulate the establishment of ESD system, EPA, packaging of sensitive devices, processing of production, personnel training and assessment, establishment and inspection of internal audit system, and detection methods.

Applicable Industries

Including electronics, electrics, IT and communications, etc.

1. Enterprises requiring high static electricity protection, such as those producing wafers and magnetic heads.

2. Subordinate enterprises or suppliers of well-known multinational corporations, such as IBM, Intel etc.

3. Well-known EMS enterprises of OEM and ODM.

Key Benefits

– Systematic management of anti-static electricity;

– Reduce electrostatic damage, improve product quality and pass rate;

– Reduce complaints from customers;

– Reduce/avoid duplicate check by different customers and save costs;

– Enhance customer trust and satisfaction.

Relevant Criteria

IEC 61340-5-1:2007 standard is another new international anti-static certification standard apart from ESD S20.20:2007. It was promulgated by IEC(International Electrotechnical Commission). By August 2007, this standard has been in the state of technical specifications and has not formed international standards.

IEC61340-5-1:2007 standard is an update of ESD S20.20:2007 standard. At present, European and Japanese enterprises are more inclined to IEC61340-5-1 standard certification. For ESD S20.20:2007 certified customers, the electrostatic protection system can also be easily converted according to IEC61340-5-1:2007 standard.

What are the connections and differences between ESD S20.20 and IEC 61340-5-1?

The members of IEC61340-5-1 Technical Committee for Standards(101 Committee) mostly come from ESD S20.20 standard compilers, so there is no essential difference between them. The biggest difference is that IEC61340 is an international standard, while S20.20 is a national standard of the United States. It has obtained ANSI/ESD S20.20 certification and can be freely switched to IEC61340-5-1 certification.

Background

SNQA is the first independently recognized certification authority of ESD20.20 project in China to issue certification certificates with ESDA accreditation marks. The localized service of 10 qualified auditors in China has greatly reduced the cost of enterprise certification and simplified the procedure. It provides authoritative and professional training for customers throughout the country, and issue training certificates with ESDA accreditation marks.

Circumstances

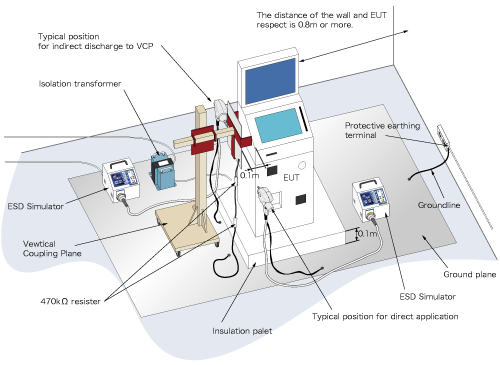

ESD testing: a.k.a. electrostatic discharge testing.

Referential standards: EN61000-4-2, corresponding to GB/T 17626.2

Types

The test is divided into:

Contact test refers to the direct contact test for the exposed metal part of the object to be tested.

Air test refers to the direct pressure of an electrostatic spray gun on the object to be tested where the object is not in direct contact with the metal (e.g. separated by a layer of plastic).

In the standard, air discharge was suggested to be “as close as possible”, but how close is that? Therefore, manufacturer A may follow 1mm, and manufacturer B may adopt 10mm, while manufacturer C uses 3mm, which will cause inconsistence by following the air discharge specification.

Models

Electrostatic discharge (ESD) can be divided into three types: Machinery ESD model, Furniture ESD model and Personnel ESD model. A brief explanation is as follows:

Machinery electrostatic discharge may occur in the automated control process, because of the friction between insulated metal parts and insulators in the automated machine, or the static electricity generated by the friction of insulating liquid or high-voltage gas, when the energy accumulates to a certain extent, it discharges nearby.

Furniture electrostatic discharge usually occurs when metal furniture rubs against insulating objects, such as pulling furniture on carpets or plastic floors, or when people stand up from chairs, static electricity is generated by friction.

Personnel electrostatic discharge is static electricity generated by human action friction, such as when we walk on the carpet wearing rubber shoes, the carpet carries positive charge and rubber shoelaces carry negative charge because of friction. Now, the sole of human foot will be induced and positively charged, while the upper body will be negatively charged. If we touch semiconductor electronic components by hand at that time, the components will be damaged.

Leave a Reply

Want to join the discussion?Feel free to contribute!