Antistatic clothing is made of special anti-static clean fabric. The fabric is made of special polyester filament and warp or zonal woven conductive fibers. It has the characteristics of high efficiency, permanent antistatic and dustproof, thin and smooth texture.

In the process of making garments, special sewing machine is used to reduce the production of particles effectively. The dust-free adhesive tape avoids the environmental pollution caused by lint come off. According to the level requirements, different styles are provided, and conductive fibers are sewn to keep the electrical continuity of each part of the garment; sleeves & trouser legs are special double-layer structure, and the inner layer uses conductive or anti-static ribs to meet the requirements of high-level dust-free environment.

- Description

- Scope of use

- Use of fabric

- Environmental requirements

- Do’s and don’ts

- Maintenance

- Packaging & storage

- Preservation

- Measurement references

- Principle of ESD

- Cleaning procedures

- Antistatic standards in China

Antistatic Garment Description

Anti-static clothing is made of anti-static and dust-proof fabric (commonly known as conductive silk), which is made of special polyester filament and high-performance permanent conductive fiber by special technology. It has excellent and lasting anti-static and dust-proof function and can effectively release human static charge.

Scope of use

Suitable for microelectronics, photoelectricity, solar energy, medicine, bioengineering, food, cosmetics, petrochemical, military and other industries which are more sensitive to electrostatic micro-dust and require higher cleanliness.

Use of fabric

- automatically corona discharge or leakage discharge

- eliminate clothing and human static electricity,

in addition to clothing, they can also be used to make anti-static hats, socks, shoes and so on. In China, the performance index conforms to the GB12014-89 standard: the charge density of cloth is less than5μC

Environmental Requirements

Relative humidity less than 30%, the charge quantity of pure cotton clothing is relatively lower than that of chemical fiber clothing , anti-static clothing made of sub-conductor material should be worn in high-voltage work place; do not take off the clothes in flammable and explosive spaces; do not wear any accessories or metal items on anti-static clothing; when wearing anti-static clothes, you should also wear antistatic clothing stipulated in GB4385. Including but not limited to electrostatic shoes, ESD caps, anti-static gloves.

Do’s and Don’ts

- Anti-static clothing should be worn when the minimum ignition energy of combustibles is below 0.25 mJ under normal situation, where explosive gas mixtures continue to emerge or exist frequently in a short time or for a long time, and where explosive gas mixtures are likely to appear.

- Do not put on or take off in flammable and explosive spaces.

- Do not wear any accessories or metal objects with anti-static clothing.

- When wearing anti-static clothes, they should also be matched with anti-static shoes. At the same time, the ground should be anti-static floor and have a grounding system as well.

- Anti-static clothing should be neat and confirmed antistatic. After use, it should be washed with soft brush or wash with soft cloth dipped in neutral detergent, do not destroy the fabric.

- Anti-static work clothes should be cleaned with neutral detergent. When washing, do not mix with other clothes. Hand-washing or washing machine soft-washing procedures should be adopted to prevent the breakage of conductive fibers.

- After wearing for a period of time, anti-static clothing should be tested. If the electrostatic performance does not meet the requirements, it can no longer be used as anti-static clothing.

- Do not put on or remove static clothing in places with danger of fire and explosion.

- Do not attach or wear metal objects with antistatic clothing in hazard places of fire and explosion.

- Outer clothing should completely cover the inner garments. The split jacket should cover the waist of the waistband.

- When wearing anti-static clothing in fire and explosion hazardous locations, you should also wear anti-static shoes stipulated by relevant national standards.

- Anti static clothing should be kept clean and antistatic. After use, brush with soft brush or soft cloth dipped in neutral detergent, ensuring not to damage the cloth fiber.

Maintenance

Packaging & Storage

In transportation, it should be noted that there must be a cover on the anti-static work clothes, and that the packaging should not be damaged so that it can prevent sun and high temperature contact. Dragging with hooks is strictly prohibited during handling.

Antistatic work clothes should be stored in dry and ventilated warehouses to prevent mildew and rot. During storage, keep a distance of 200mm from floor and walls and 1m away from all heating items . Direct sunlight should be avoided and outdoor placement prohibited.

Appropriate moth proofing measures should be taken when packaging and storing wool knitted antistatic clothing.

Preservation

Anti-static work clothes should be cleaned with neutral detergent. Do not mix with other clothes. Hand washing or washing machine soft washing procedures should be adopted to avoid the damage of conductive fibers. Washing water temperature should be below 40 degrees Celsius, rinse with normal temperature. The washing period is as short as possible, but must be rinsed sufficiently to remove residual detergent. Antistatic work clothes with flame retardant and oil proof properties shall not be used with bleach or organic solvents for decontamination.

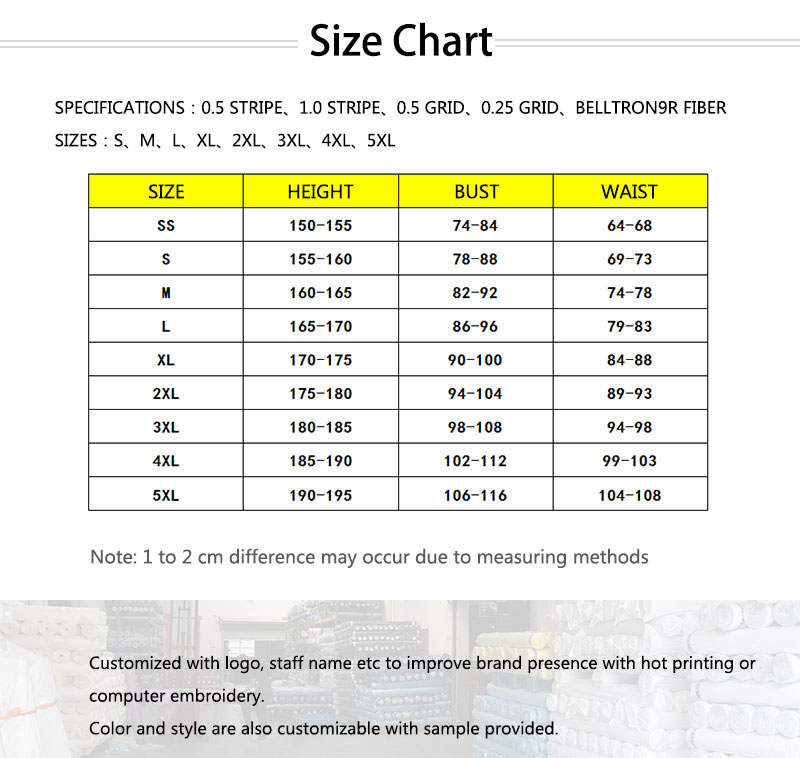

Measurement References

GB 1335 Clothing size series

GB 2668 Men’s and women’s single coat specifications series

GB 2669 Men’s and women’s trousers specifications series

GB 2828 Batch by lot inspection sampling procedure and sampling table (for continuous batch inspection)

GB 3923 Determination of breaking strength and breaking elongation of woven fabric (strip method)

GB 4288 Household electric washing machine

GB 4385 Antistatic rubber soles and conductive rubber soles before safety technology

Principle of ESD

(2) Conductive fibers refer to all or part of the fibers made of conductive or sub-conductive materials of metals or organics. Their volume resistivity ρv~is between 104 and 109Ω/cm. The distribution of irradiated conductive components in the fibers can be divided into three types: conductive component homogeneous, conductive component covering and conductive component composite.

(3) Anti-static work clothes made of conductive fibers are added to chemical fibre fabrics. Their power dissipation is based on two mechanisms: charge leakage and neutralization. When grounded, the static electricity on the fabric can be released to the earth through conductive fibers or being neutralized by the corona discharge of conductive fibers; when not grounded, it can be eliminated by the weak corona discharge of conductive fibers.

Cleaning Procedures

Sorting: After receiving the customer’s laundry to be sorted, stored them in a covered plastic box, to prevent aggravation of pollution.

Pretreatment: Take maintenance treatments to breakage, dropping buttons etc. Pre-decontamination should be carried out for the special dirt cleaning works.

Dust-free cleaning: Pretreated uniforms are cleaned by a special channel structure washing machine in the non-control area first, then they enter the control area (clean room).

Dust-free drying: Cleaned and purified uniforms are dried in the clean room by a dust-free dryer (the drying hot air used is filtered by HEPA).

Folding inspection: Fold the dry clean clothes, and the appearance inspection is carried out at the same time. If it fails to pass the inspection, it should be put back into the cleaning process to clean or be replaced.

Cleanliness test: Helmke Drum tester, which can test the number of dust particles in cleanliness grade of cleaned uniforms

ESD test: ESD performance check to ensure the anti-static performance of the cleaning garment.

Purification Packaging: Through all the inspection of the purified uniforms, after the purification packaging bag sealed packaging, it will become a qualified product.

Antistatic Standards in China

I. Standard scope:

This standard specifies the technical requirements, testing methods, inspection rules and identification of antistatic clothing.

This standard is applicable to antistatic clothing that may be used in electric shock, fire and explosion hazardous places.

The antistatic clothing defined in this standard does not apply to the power supply voltage resistence.

Standard number: GB 12014-2009

Chinese term: fáng jìng diàn fú(instead of standard number: GB 12014-1989 antistatic clothing).

II. Terms and definitions

The following terms and definitions apply to this standard.

Static protective clothing

In order to prevent the accumulation of static electricity on clothing, anti-static fabrics are used as fabrics, and the work clothes are sewn according to the prescribed style and structure.

Static protective fabric

When weaving, a fabric made of yarn blended with conductive fibers or woven with conductive filaments can also be treated and protected fabric with electrostatic properties.

Conductive fiber

All or part of the conductive material made of metal or organic materials or fibers made of static dissipative material.

Electrostatic Dissipative Material

The surface resistivity is greater than or equal to 1 x 10^5 ohms but less than 1 * 10^11 ohms.

Surface resistivity

A physical quantity representing the electrical conductivity of an object.

Point to point resistance

In a given time, the ratio of the applied current and voltage between the two electrodes on the surface of the material to the DC current flowing through them is applied.

III. Technical requirements:

1) Fabric:

– Appearance quality: It is required that the fabric should be free from damage, spots, dirt or other defects affecting the anti-static performance of the fabric.

– Testing parameters: fabric is tested by point to point resistance method, and the technical parameters are shown in the following table.

|

Test project

|

Technical requirements

|

|

|

Class A

|

Class B

|

|

|

Point to point resistance/Ω

|

1 x 10—- 1 x 10

|

1 x 10—- 1 x 10

|

2) Clothing:

– Appearance quality: there should be no defects, spots, dirt and other defects affecting the wearing performance.

– Structural style: Clothing structure should be safe and hygienic, conducive to the normal physiological requirements and health of human body; clothing should be easy to wear and adapt to the physical activities of the operation; clothing style should be simple and easy to use according to the requirement of use.

– Sewing: sewing threads in all parts are straight, neat and firm. The upper and lower tightness is suitable, no jumping needle, and the needles at the landing and landing needles should be returned.

– Test parameters: antistatic clothing is measured by charged quantity test method. The technical parameters are shown in the following table.

|

Test project

|

Technical requirements

|

|

|

Class A

|

Class B

|

|

|

Charge quanity/(μC per item)

|

<0.20

|

0.20 —- 0.60

|

3) Washing:

Anti static clothing and fabrics must be washed per the regulations before testing.

Leave a Reply

Want to join the discussion?Feel free to contribute!